NFPA 96

Standard for ventilation control and fire protection of commercial cooking operations

The NFPA 96 is the basis from which our certification is obtained

“Being Taught The NFPA 96 Standards by A Technical Committee Member Is The Only Way I Suggest That You Learn Them. This Way You Are Hearing Them Straight From A Person Who Is Actually Helping The Standards Be Formed.”

Here at Certified Hood & Duct Cleaners Association we teach and follow the NFPA 96 standards.

To acquire the latest NFPA 96 standards, click the button below for purchase.

12.4 * Inspection for Grease Buildup.

The entire exhaust system shall be inspected for grease buildup by a properly trained, qualified, and certified person(s) acceptable to the authority having jurisdiction and in accordance with Table 12.4.

Table 12.4 Schedule of Inspection for Grease Buildup

| Type or Volume of Cooking | Inspection Frequency |

|---|---|

| Systems serving solid fuel cooking operations | Monthly |

| *Systems serving high-volume cooking operations | Quarterly |

| Systems serving moderate-volume cooking operations | Semiannually |

| †Systems serving low-volume cooking operations | Annually |

*High-volume cooking operations include 24-hour cooking, charbroiling, and wok cooking.

†Low-volume cooking operations include churches, day camps, seasonal businesses, and senior centers.

Listed hoods containing mechanical or fire-actuated dampers, internal washing components, or other mechanically operated devices shall be inspected and tested by properly trained, qualified, and certified persons every 6 months or at frequencies recommended by the manufacturer in accordance with their listings.

12.6.1

If, upon inspection, the exhaust system is found to be contaminated with deposits from grease-laden vapors, the contaminated portions of the exhaust system shall be cleaned by a properly trained, qualified, and certified person(s) acceptable to the authority having jurisdiction.

12.6.1.1

A measurement system of deposition shall be established to trigger a need to clean when the exhaust system is inspected at the frequencies in Table 12.4.

12.6.1.1.1

Hoods, grease removal devices, fans, ducts, and other appurtenances shall be cleaned to remove combustible contaminants to a minimum of 0.002 in. (50 μm).

12.6.1.1.2

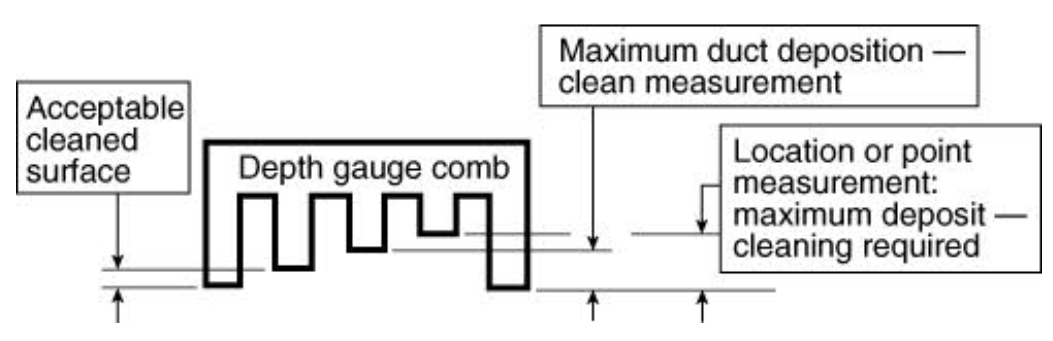

A grease depth gauge comb as shown in Figure 12.6.1.1.2 shall be placed upon the surface to measure grease depth.

Figure 12.6.1.1.2 Depth Gauge Comb.

12.6.1.1.3

Where a measured depth of 0.078 in. (2000 μm) is observed, the surfaces shall be cleaned in accordance with 12.6.1.

12.6.1.1.4

Where a measured depth of 0.125 in. (3175 μm) is observed in a fan housing, the surfaces shall be cleaned in accordance with 12.6.1.

12.6.2

Hoods, grease removal devices, fans, ducts, and other appurtenances shall be cleaned to remove combustible contaminants prior to surfaces becoming heavily contaminated with grease or oily sludge.

12.6.3

At the start of the cleaning process, electrical switches that could be activated accidentally shall be locked out.

12.6.4

Components of the fire suppression system shall not be rendered inoperable during the cleaning process.

12.6.5

Fire-extinguishing systems shall be permitted to be rendered inoperable during the cleaning process where serviced by properly trained and qualified persons.

12.6.6

Flammable solvents or other flammable cleaning aids shall not be used.

12.6.7

Cleaning chemicals shall not be applied on fusible links or other detection devices of the automatic extinguishing system.

12.6.8

After the exhaust system is cleaned, it shall not be coated with powder or other substance.

12.6.9

When cleaning procedures are completed, all access panels (doors) and cover plates shall be restored to their normal operational condition.

12.6.10

When an access panel is removed, a service company label or tag preprinted with the name of the company and giving the date of inspection or cleaning shall be affixed near the affected access panels.

12.6.11

Dampers and diffusers shall be positioned for proper airflow.

12.6.12

When cleaning procedures are completed, all electrical switches and system components shall be returned to an operable state.

12.6.13

When an exhaust system is inspected or cleaned, a certificate showing the name of the servicing company, the name of the person performing the work, and the date of inspection or cleaning shall be maintained on the premises.

12.6.14

After cleaning or inspection is completed, the exhaust cleaning company and the person performing the work at the location shall provide the owner of the system with a written report that also specifies areas that were inaccessible or not cleaned.

12.6.15

Where required, certificates of inspection and cleaning and reports of areas not cleaned shall be submitted to the authority having jurisdiction.

12.6.16

Metal containers used to collect grease drippings shall be inspected or emptied at least weekly.

12.7.1

Inspection and servicing of the cooking equipment shall be made at least annually by properly trained and qualified persons.

12.7.2 *

Cooking equipment that collects grease below the surface, behind the equipment, or in cooking equipment flue gas exhaust, such as griddles, deep-fat fryers, or charbroilers, shall be inspected and, if found with grease accumulation, cleaned by a properly trained, qualified, and certified person(s) acceptable to the authority having jurisdiction.

3.3.1 Access Panel.

A closure device used to cover an opening into a duct, an enclosure, equipment, or an appurtenance.

3.3.2 Air Intakes.

An opening in a building’s envelope whose purpose is to allow outside air to be drawn into the structure to replace inside air that is removed by exhaust systems or to improve the quality of the inside air by providing a source of air having a lower concentration of odors, suspended particles, or heating content.

3.3.3 Air Pollution Control Devices.

Equipment and devices used for the purpose of cleaning air passing through them or by them in such a manner as to reduce or remove the impurities contained therein.

3.3.4 Appliance Flue Outlet.

The opening or openings in a cooking device where vapors, combustion gases, or both leave the cooking device.

3.3.5 Appurtenance.

An accessory or a subordinate part that enables the primary device to perform or improves its intended function.

3.3.6 Assembly Occupancy.

An occupancy (1) used for a gathering of 50 or more persons for deliberation, worship, entertainment, eating, drinking, amusement, awaiting transportation, or similar uses; or (2) used as a special amusement building, regardless of occupant load. [101, 2021]

3.3.7 Automatic.

Performing a function without the necessity of human intervention.

3.3.8 Baffle Plate.

An object placed in or near an appliance to change the direction of or to retard the flow of air, air-fuel mixtures, or flue gases.

3.3.9 Broiler.

3.3.9.1 High Broiler.

See 3.3.9.3, Upright Broiler.

3.3.9.2 Salamander Broiler.

See 3.3.9.3, Upright Broiler.

3.3.9.3 Upright Broiler.

An appliance used in the preparation of food whereby foods are exposed to intense radiant heat, and perhaps to convective heat, with the food or the food and the radiant source not limited to a horizontal mode.

3.3.10 Certified.

A formally stated recognition and approval of an acceptable level of competency acceptable to the AHJ.

3.3.12 Clean(ing).

For kitchen exhaust systems and cooking equipment, the act of removing grease, oil deposits, and other residue.

3.3.13 Clearly Identified.

Capable of being recognized by a person of normal vision without causing uncertainty and indecisiveness about the location or operating process of the identified item.

3.3.17 Detection Devices.

Electrical, pneumatic, thermal, mechanical, or optical sensing instruments, or subcomponents of such instruments, whose purpose is to cause an automatic action upon the occurrence of some preselected event.

3.3.18 Discharge.

The final portion of a duct or pipe where the product being conveyed is emptied or released from confinement; the termination point of the pipe or duct.

3.3.19 Duct Termination.

The final or intended end-portion of a duct system that is designed and functions to fulfill the obligations of the system in a satisfactory manner.

3.3.20 Ducts (or Duct System).

A continuous passageway for the transmission of air and vapors that, in addition to the containment components themselves, might include duct fittings, dampers, plenums, and/or other items or air-handling equipment.

3.3.20.2 Grease Ducts.

A containment system for the transportation of air and grease vapors that is designed and installed to reduce the possibility of the accumulation of combustible condensation and the occurrence of damage if a fire occurs within the system.

3.3.21 Easily Accessible.

Within comfortable reach, with limited dependence on mechanical devices, extensions, or assistance.

3.3.22 Enclosure.

3.3.22.1 Continuous Enclosure.

A recognized architectural or mechanical component of a building having a fire resistance rating as required for the structure and whose purpose is to enclose the vapor removal duct for its full length to its termination point outside the structure without any portion of the enclosure having a fire resistance rating less than the required value.

3.3.22.2 Grease Duct Enclosure.

3.3.22.2.1 Factory-Built Grease Duct Enclosure.

A listed factory-built grease duct system evaluated as an enclosure system for reduced clearances to combustibles and as an alternative to a duct with its fire-rated enclosure.

3.3.22.2.2 Field-Applied Grease Duct Enclosure.

A listed system evaluated for reduced clearances to combustibles and as an alternative to a duct with its fire-rated enclosure.

3.3.23 Equipment.

3.3.23.1 Fire-Extinguishing Equipment.

Automatic fire-extinguishing systems and portable fire extinguishers provided for the protection of grease removal devices, hoods, duct systems, and cooking equipment, and listed for such use.

3.3.23.2 Solid Fuel Cooking Equipment.

Cooking equipment that utilizes solid fuel.

3.3.24 Filter.

3.3.24.1 Grease Filter.

A removable component of the grease removal system designed to capture grease and direct it to a safe collection point.

3.3.24.2 Mesh Filter.

A filter construction consisting of a net made from intersecting strands with a space between each strand.

3.3.25 Fire Resistance Rating.

The time, in minutes or hours, that materials or assemblies have withstood a fire exposure as established in accordance with the test procedures of ASTM E119 or UL 263.

3.3.26 Fire Wall.

A wall separating buildings or subdividing a building to prevent the spread of the fire and having a fire resistance rating and structural stability.

3.3.27 Fume Incinerators.

Devices that use intense heat or fire to break down and/or oxidize vapors and odors contained in gases or air being exhausted into the atmosphere.

3.3.28 Fusible Link.

A form of fixed temperature heat-detecting device sometimes employed to restrain the operation of an electrical or mechanical control until its designed temperature is reached.

3.3.29 Grease.

Rendered animal fat, vegetable shortening, and other such oily matter used for the purposes of and resulting from cooking and/or preparing foods.

3.3.30 Grease Removal Devices.

A system of components designed and intended to process vapors, gases, and/or air as it is drawn through such devices by collecting the airborne grease particles and concentrating them for further action at some future time, leaving the exiting air with a lower amount of combustible matter.

3.3.31 Greasetight.

Constructed and performing in such a manner as not to permit the passage of any grease under normal cooking conditions.

3.3.32 High Limit Control Device.

An operating device installed and serving as an integral component of a deep fat fryer that provides secondary limitation of the grease temperature by automatically disconnecting the thermal energy input when the temperature limit is exceeded.

3.3.33 Hood.

A device provided for a cooking appliance(s) to direct and capture grease-laden vapors and exhaust gases.

3.3.34 Interconnected.

Mutually assembled to another component in such a manner that the operation of one directly affects the other or that the contents of one specific duct system are allowed to encounter or contact the products being moved by another duct system.

3.3.35 Liquidtight.

Constructed and performing in a way that prevents the passage of any liquid at any temperature.

3.3.36 Maintenance.

Work including, but not limited to, repair, replacement, and service, performed to ensure that equipment operates properly.

3.3.37 Material.

3.3.37.1 Combustible Material.

Any material that will burn regardless of its autoignition temperature.

3.3.37.2 Limited-Combustible (Material).

Material with limited burning characteristics that, when in the form in which it is used, does not comply with the definition of noncombustible material. (See 4.8.2.)

3.3.37.3 Noncombustible Material.

See 4.8.1.

3.3.38 Noncompliant.

Not meeting all applicable requirements of this standard.

3.3.40 Qualified.

A competent and capable person who has met the requirements and training for a given field acceptable to the AHJ.

3.3.41 Recirculating Systems.

Systems for control of smoke or grease-laden vapors from commercial cooking equipment that do not exhaust to the outside.

3.3.42 Removable.

Capable of being transferred to another location with a limited application of effort and tools.

3.3.43 Replacement Air.

Air deliberately brought into the structure, then specifically to the vicinity of either a combustion process or a mechanically or thermally forced exhausting device, to compensate for the vapor and/or gases being consumed or expelled.

3.3.44 Single Hazard Area.

Where two or more hazards can be simultaneously involved in fire by reason of their proximity, as determined by the authority having jurisdiction.

3.3.45 Solid Cooking Fuel.

Any solid, organic, consumable fuel such as briquettes, mesquite, hardwood, or charcoal.

3.3.46 Solvent.

A substance (usually liquid) capable of dissolving or dispersing another substance; a chemical compound designed and used to convert solidified grease into a liquid or semiliquid state to facilitate a cleaning operation.

3.3.47 Space.

3.3.47.1 Concealed Spaces.

That portion(s) of a building behind walls, over suspended ceilings, in pipe chases, and in attics whose size might normally range from 13∕ 4 in. (44.45 mm) stud spaces to 8 ft (2.44 m) interstitial truss spaces and that might contain combustible materials such as building structural members, thermal and/or electrical insulation, and ducting.

3.3.47.2 Confined Space.

A space whose volume is less than 50 ft3/1000 Btu/hr (1.42 m3/293 W) of the aggregate input rating of all appliances installed in that space.

3.3.48 Spark Arrester.

A device or method that minimizes the passage of airborne sparks and embers into a plenum.

IMPORTANT: This is an excellent reference manual. Purchase of this book is strictly optional, but it is recommended for those who are serious about this as their career.

Click here to order your NFPA 96 manual

Get Certified and Level Up Your Hood Cleaning Business!